GMG’s Graphene Aluminium-Ion Battery Update: Minimal Temperature Rise Identified While Fast Charging

BRISBANE, Australia, Feb. 14, 2024 — Graphene Manufacturing Group Ltd. (TSX-V: GMG) (“GMG” or the “Company”) provides the latest progress update on its Graphene Aluminium-Ion Battery technology (“G+AI Battery”) being developed by GMG and the University of Queensland (“UQ”).

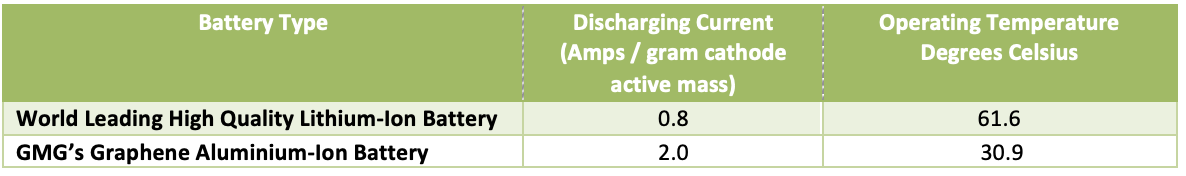

The Company is pleased to announce that it has identified minimal temperature rise when charging and discharging GMG’s Graphene Aluminium-Ion Battery. This is observed when charging and discharging multiple times at high C- rates (C rate measures the current in a which a battery can be charged or discharged, eg. 1 C rate the battery should be able to be fully discharged in 1 hour). As shown in Figure 1, the temperature of a high-quality lithium-ion battery, produced by a world leading brand, can exceed 60 degrees Celsius when being discharged at the maximum current allowed (4.8 C-rate – an estimated 0.8 A/g on the cathode active material mass). By comparison, GMG’s Graphene Aluminium-Ion Battery temperature is 29 degrees Celsius when it is discharged at even higher current density (20 C-rate – approximately 2.0 A/g on the cathode active mass). The temperatures of both batteries were taken with the room temperature at 23.5 degrees Celsius (+/- 0.5 degrees Celsius).

https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-300x45.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-1024x152.png 1024w, https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-768x114.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-720x107.png 720w" alt="" width="1186" height="176" class="wp-image-12266" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" decoding="async" />

https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-300x45.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-1024x152.png 1024w, https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-768x114.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/Screen-Shot-2024-02-14-at-7.19.19-AM-720x107.png 720w" alt="" width="1186" height="176" class="wp-image-12266" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" decoding="async" /> https://graphenemg.com/wp-content/uploads/2024/02/GMG-Picture1-300x239.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/GMG-Picture1-768x611.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/GMG-Picture1-720x572.png 720w" alt="" width="800" height="636" class="wp-image-12268" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 534px;" decoding="async" />

https://graphenemg.com/wp-content/uploads/2024/02/GMG-Picture1-300x239.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/GMG-Picture1-768x611.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/GMG-Picture1-720x572.png 720w" alt="" width="800" height="636" class="wp-image-12268" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 534px;" decoding="async" />Figure 1: Thermal Image of Lithium-Ion Battery (left) with Thermal Image of Graphene Aluminium-Ion Battery (right)

The Company intends to validate with further testing the possibility that its battery may not need thermal management, even at high charge and discharge rates. This creates the potential for significant cost reduction at the system level and highly reduced system cost.

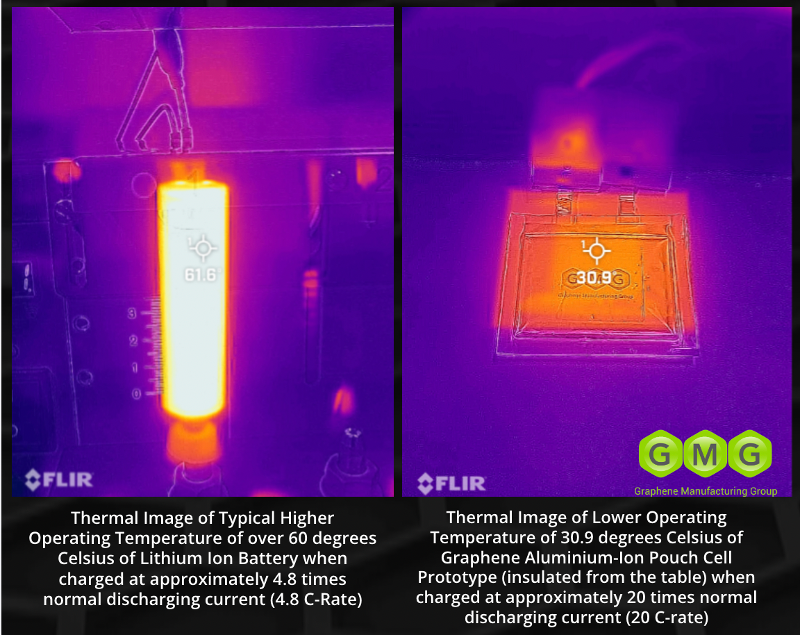

- GMG’s Graphene Aluminium-Ion Battery may not need a thermal management system when used in an electric vehicle battery pack or an energy storage system, which will lead to a simpler, more cost effective and higher energy density battery pack. Most Lithium-Ion Battery Packs require a thermal management system, such as the one shown in Figure 2 below.

https://graphenemg.com/wp-content/uploads/2024/02/GMG2-Picture1-300x192.png 300w" alt="" width="711" height="455" class="wp-image-12269" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 470px;" loading="lazy" decoding="async" />

https://graphenemg.com/wp-content/uploads/2024/02/GMG2-Picture1-300x192.png 300w" alt="" width="711" height="455" class="wp-image-12269" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 470px;" loading="lazy" decoding="async" />Figure 2: A typical Lithium-Ion Battery thermal management system[1]

- The elimination of thermal management can potentially reduce the weight of an electric vehicle battery pack by up to 16%. For example, the thermal management system of a Lithium-Ion Battery Pack can weigh up to 80 kg out of a total of 480 kg. Such a weight reduction achieved through the elimination of thermal management translates into more energy volumetrically (approximately 10%), as well as vehicle mass reduction for more range. Additional range improvements could be expected to come from no thermal management parasitic drain on the battery during operation.

- Furthermore, because GMG’s Graphene Aluminium-Ion Battery has no combustible volatile organic materials, it is more resilient to the risk of chemical fires, such as those that have occurred with Lithium-Ion Batteries.

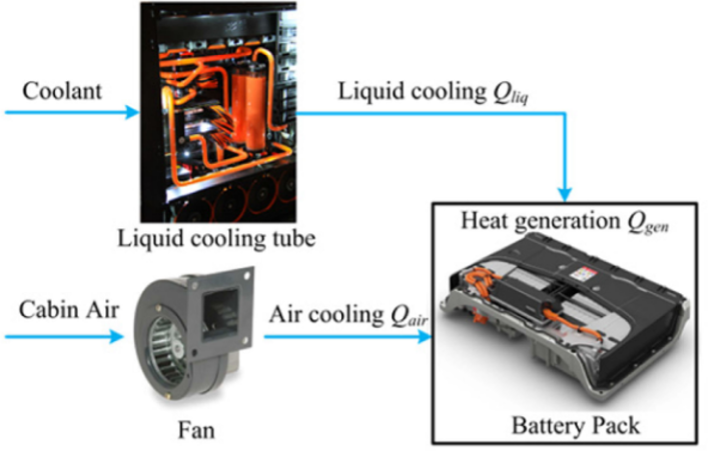

Battery Technology Readiness Level

The battery technology readiness level (“BTRL”) of the Graphene Aluminium-Ion technology remains at Level 4 (see Figure 4). GMG is currently optimizing electrochemical behaviour for pouch cells via ongoing laboratory experimentation. When GMG commissions its Pilot Plant, it is anticipated that the Company’s battery technology will progress to BTRL 7 and 8 since the equipment and process to make the Graphene Aluminium-Ion batteries are the same as those used to make Lithium Ion Batteries.

https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-300x81.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-1024x277.png 1024w, https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-768x208.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-720x195.png 720w" alt="" width="1108" height="300" class="wp-image-12267" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" loading="lazy" decoding="async" />

https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-300x81.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-1024x277.png 1024w, https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-768x208.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/fig3Picture1-720x195.png 720w" alt="" width="1108" height="300" class="wp-image-12267" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" loading="lazy" decoding="async" />Figure 3: Battery Technology Readiness Level

Source: “The Battery Component Readiness Level (BC-RL) Framework: A technology-specific development framework”, Matthew Greenwood et al

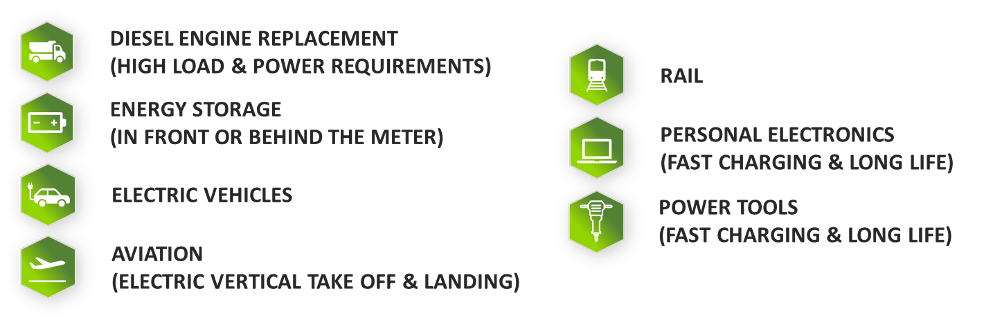

Next Steps Toward Commercialisation & Market Applications

The Company continues to see a broad range of applications for a completed GMG Graphene Aluminium Ion Battery – utilising its ultra-high power-density and nominal energy density characteristics. Along with Rio Tinto, a range of global companies have confidentially expressed their interest in working with GMG in the following vertical sectors:

https://graphenemg.com/wp-content/uploads/2024/02/GMGfig4Picture1-300x99.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig4Picture1-768x253.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig4Picture1-720x237.png 720w" alt="" width="987" height="325" class="wp-image-12270" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" loading="lazy" decoding="async" />

https://graphenemg.com/wp-content/uploads/2024/02/GMGfig4Picture1-300x99.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig4Picture1-768x253.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig4Picture1-720x237.png 720w" alt="" width="987" height="325" class="wp-image-12270" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" loading="lazy" decoding="async" />Next Generation Battery Performance

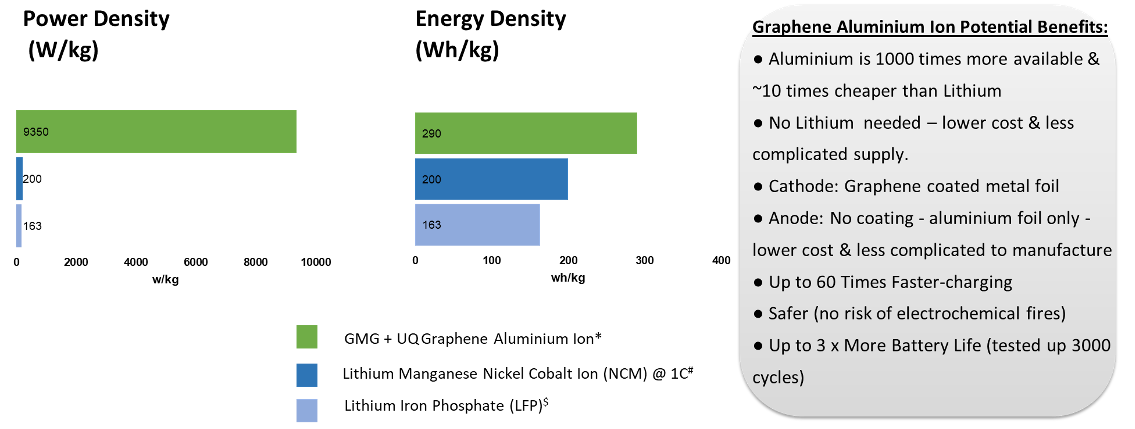

GMG’s next generation Graphene Aluminium Ion Battery performance data (as tested and calculated on coin cells), as compared to the most commonly available lithium-ion batteries, is shown below in Figure 5, with a list of its beneficial characteristics.

Performance results for the pouch cells could be significantly different and will be communicated upon successfully producing a repeatable and fully 3rd party tested 1000 mAh+ battery pouch cell.

https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-300x113.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-1024x387.png 1024w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-768x290.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-720x272.png 720w" alt="" width="1135" height="429" class="wp-image-12271" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" loading="lazy" decoding="async" />

https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-300x113.png 300w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-1024x387.png 1024w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-768x290.png 768w, https://graphenemg.com/wp-content/uploads/2024/02/GMGfig5Picture1-720x272.png 720w" alt="" width="1135" height="429" class="wp-image-12271" style="box-sizing: border-box; height: auto; max-width: 100%; border: 0px none; vertical-align: bottom; width: 839px;" loading="lazy" decoding="async" />Figure 4: Graphene Aluminium Ion Battery Comparative Performance Data (for coin cells)

About GMG

GMG is a disruptive Australian-based clean-tech company listed on the TSXV (TSXV: GMG) that produces graphene and hydrogen by cracking methane (natural gas) instead of mining graphite. By using the company’s proprietary process, GMG can produce high quality, scalable, ‘tuneable’ and no/low contaminant graphene – enabling demonstrated cost and environmental improvements in a number of world-scale planet-friendly/clean-tech applications. Using this low input cost source of graphene, the Company is developing value-added products that target the massive energy efficiency and energy storage markets. The Company is pursuing additional opportunities for GMG Graphene, including developing next-generation batteries, collaborating with world-leading universities in Australia, and investigating the opportunity to enhance the performance of lubricant oil and performance enhanced HVAC-R coating system.

GMG’s 4 critical business objectives are:

- Produce Graphene and improve/scale cell production processes

- Build Revenue from Energy Savings Products

- Develop Next-Generation Battery

- Develop Supply Chain, Partners & Project Execution Capability

For further information please contact:

- Craig Nicol, Chief Executive Officer & Managing Director of the Company at craig.nicol@graphenemg.com, +61 415 445 223

- Leo Karabelas at Focus Communications Investor Relations, leo@fcir.ca, +1 647 689 6041

www.graphenemg.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accept responsibility for the adequacy or accuracy of this news release.

Cautionary Note Regarding Forward-Looking Statements

This news release includes certain statements and information that may constitute forward-looking information within the meaning of applicable Canadian securities laws. Forward-looking statements relate to future events or future performance and reflect the expectations or beliefs of management of the Company regarding future events. Generally, forward-looking statements and information can be identified by the use of forward-looking terminology such as “intends”, “expects” or “anticipates”, or variations of such words and phrases or statements that certain actions, events or results “may”, “could”, “should”, “would” or will “potentially” or “likely” occur. This information and these statements, referred to herein as “forward‐looking statements”, are not historical facts, are made as of the date of this news release and include without limitation, statements regarding the development of the Company’s pouch cell battery, the relative safety and performance of the G+AI Battery compared to lithium-ion batteries, the ability of the G+AI Battery to be used in an electric vehicle battery pack without the need for a cooling system and the potential benefits therefrom, the Company’s focus on making a repeatable 1000 mAh pouch cell and the expected timing of producing a repeatable 1000 mAh pouch cell, that the Company will review the investment decision to procure and install an automated pouch cell battery pilot plant in its Richlands Australia facility and the potential to build a commercial factory if the pilot plant and customer trials are successful, the timing of customer testing for an 1000 mAh pouch cell, the ongoing optimization of the pouch cell, and the potential applications for the G+AI Battery.

Such forward-looking statements are based on a number of assumptions of management, including, without limitation, assumptions relating to the relative safety of the G+AI Battery when compared to lithium ion batteries, that the G+AI Battery could be used in an electric vehicle battery pack without a cooling system, that the G+AI Battery has a lower risk of chemical fire than lithium ion batteries due to the difference in material, that the Company’s focus will remain on making a repeatable 1000 mAh pouch cell, that the Company will be successful in creating a repeatable 1000 mAh pouch cell and will achieve this in the first half of 2024, that the Company will review the investment decision to procure and install an automated pouch cell battery pilot plant in its Richlands Australia facility, that the Company may build a commercial factory if the pilot plant and customer trials are successful, that the Company will optimize electrochemical behaviour for pouch cells via ongoing laboratory experimentation, that the Company will communicate performance data following the successful production of a 1000 mAh pouch cell. Additionally, forward-looking information involves a variety of known and unknown risks, uncertainties and other factors which may cause the actual plans, intentions, activities, results, performance or achievements of GMG to be materially different from any future plans, intentions, activities, results, performance or achievements expressed or implied by such forward-looking statements. Such risks include, without limitation: that the G+AI Battery will not be as safe or perform as well as lithium ion batteries, that the G+AI Battery will not be able to be used in an electric vehicle battery pack without a cooling system, that the G+AI Battery does not have a lower risk of chemical fires than a lithium ion battery, that the Company will change its focus away from creating a repeatable 1000 mAh pouch cell, that the Company will not be successful in developing a repeatable 1000 mAh pouch cell on the expected timeline, if at all, that the Company will choose not to proceed with a pilot plant, that the Company will not proceed to customer testing, that the Company will not build a commercial factory even if the pilot plant and customer trials are successful, that the Company will be unable to optimize the electrochemical behaviour of the pouch cell though laboratory experimentation or at all, that the Company will not communicate the performance data of a 1000 mAh cell if it is achieved, risks relating to the extent and duration of the conflict in Eastern Europe and its impact on global markets, the volatility of global capital markets, political instability, the failure of the Company to obtain regulatory approvals, attract and retain skilled personnel, unexpected development and production challenges, unanticipated costs and the risk factors set out under the heading “Risk Factors” in the Company’s annual information form dated October 12, 2023 available for review on the Company’s profile at www.sedarplus.ca.

Although management of the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking statements or forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking statements and forward-looking information. Readers are cautioned that reliance on such information may not be appropriate for other purposes. The Company does not undertake to update any forward-looking statement, forward-looking information or financial out-look that are incorporated by reference herein, except in accordance with applicable securities laws. We seek safe harbor.

[1] “A Real-Time Battery Thermal Management Strategy for Connected and Automated Hybrid Electric Vehicles (CAHEVs) Based on Iterative Dynamic Programming”, 6 June 2018, Chong Zhu et al.